Unveiling the Differences: 6063 vs 6061 Aluminum Alloys

Aluminum alloys play a pivotal role across various industries, thanks to their remarkable properties. Among the plethora of aluminum alloys available, 6063 and 6061 stand out prominently. Understanding the distinctions between these alloys is crucial for making informed decisions in engineering and manufacturing. In this comprehensive guide, we delve into the properties, applications, and differences between 6063 and 6061 aluminum alloys.

Properties of 6063 Aluminum

6063 aluminum alloy is renowned for its composition and alloying elements that contribute to its unique set of properties. Comprising primarily of aluminum, magnesium, and silicon, 6063 exhibits impressive formability and excellent corrosion resistance. Its mechanical properties, including strength and hardness, make it a preferred choice for applications demanding versatility.

In terms of thermal properties, 6063 aluminum demonstrates efficient heat dissipation, making it suitable for applications where temperature management is critical. The alloy’s corrosion resistance further enhances its durability, making it a reliable choice in various environments.

Properties of 6061 Aluminum

Contrasting with 6063 some time we call aircraft grade aluminum 6061, the 6061 aluminum alloy possesses a different composition, primarily consisting of aluminum, magnesium, and silicon. This alloy is known for its robust mechanical properties, excelling in strength, hardness, and formability. The thermal properties of 6061 aluminum contribute to its suitability for applications requiring heat resistance.

Corrosion resistance is another hallmark of 6061 aluminum, ensuring longevity in diverse environmental conditions. These properties collectively make 6061 aluminum a staple in industries demanding structural integrity and reliability.

Applications

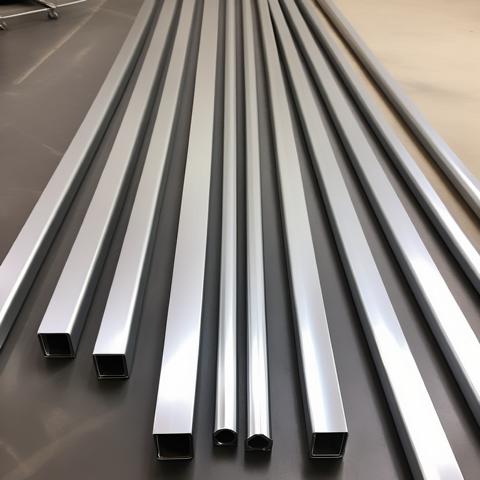

6063 Aluminum Applications: GC Precision CNC Machining China company often employs 6063 aluminum for various applications. Its excellent formability and corrosion resistance make it a preferred choice for extruded profiles, architectural frames, and intricate shapes in construction and automotive industries. Additionally, 6063 is favored in the production of lightweight consumer goods and electronic enclosures.

6061 Aluminum Applications: GC Precision CNC Machining China company frequently utilizes 6061 aluminum in applications where strength and durability are paramount. This alloy finds its place in aerospace components, marine structures, and high-stress structural parts. Its versatility extends to the production of automotive components, bicycle frames, and precision instruments.

Differences Between 6063 and 6061 Aluminum

The differences between these alloys lie in their alloy compositions, affecting their mechanical and thermal properties. 6061 aluminum, with higher levels of magnesium, exhibits superior strength compared to 6063. Conversely, 6063, with elevated silicon content, excels in formability and corrosion resistance.

These distinctions are crucial in selecting the appropriate alloy for specific applications. Engineers and manufacturers must weigh factors such as strength requirements, formability, and environmental considerations to make informed choices.

Selection Criteria

When choosing between 6063 and 6061 aluminum, several factors come into play. Application requirements, environmental conditions, and cost implications should be carefully considered. GC Precision CNC Machining China company, with its expertise in CNC machining, understands the importance of selecting the right alloy for optimal results in precision manufacturing.

Performance Comparisons

Strength-to-Weight Ratio: 6061 aluminum’s higher strength-to-weight ratio makes it ideal for applications demanding structural integrity without compromising weight. This makes it a preferred choice in aerospace and automotive industries where lightweight components with robust strength are paramount.

Machinability: GC Precision CNC Machining China company leverages the machinability of both alloys for precision CNC machining. While 6063 offers excellent formability, 6061’s machinability allows for intricate designs and precise detailing.

Weldability: Both alloys exhibit good weldability, enabling seamless integration in manufacturing processes. However, the specific welding techniques may vary, and consideration must be given to the desired outcome and project requirements.

Anodizing Potential: 6061 aluminum’s enhanced anodizing potential makes it suitable for applications requiring surface treatments for corrosion resistance or aesthetic purposes. This feature adds to the versatility of 6061 in various industries.

Market Trends and Considerations

In the dynamic landscape of aluminum alloy applications, staying abreast of market trends is crucial. GC Precision CNC Machining China company observes the current market demands for 6063 and 6061 aluminum, adapting its precision machining capabilities to meet industry requirements. Emerging trends in aluminum alloy applications, such as advancements in lightweight materials for electric vehicles, guide strategic decisions for manufacturers.

Conclusion

In conclusion, the choice between 6063 and 6061 aluminum alloys depends on the specific requirements of the application. GC Precision CNC Machining China company, with its commitment to precision and quality, recognizes the nuances of each alloy and tailors its manufacturing processes accordingly. As technology and industry needs evolve, these aluminum alloys will continue to play a vital role in shaping the future of precision engineering and manufacturing.

Are you in need of high-quality aluminum die casting services? Look no further than CNM Tech China die casting manufacturer! Our team of experts specializes in aluminum, zinc, and magnesium die casting, as well as machining parts, metal stamping, and plastic molds making.

With over 18 years of experience, you can trust that our die casting products are exemplary and cost-effective. We employ advanced equipment and machinery to ensure the highest quality solutions.

We have been made many type of aluminum die casting, zinc die casting, magnesium die casting from flow meter housing and valves to lighting fixture parts, automobile parts, and decorative hardware, we manufacture a wide range of products to meet your needs. And, as an added bonus, we also export various aluminum casting, zinc die casting, and magnesium casting products, as well as machining parts and injection molded parts.

Don’t settle for subpar aluminum casting services. Choose CNM Tech die casting China manufacturer for exceptional quality and affordable prices. Contact us today to learn more about our services and how we can help meet your die casting needs!