by hyx mold | Feb 7, 2024 | plastic mold manufacture

Yes, acrylic can be injection molded. Injection molding is a widely used manufacturing process that involves melting a thermoplastic material, injecting it into a mold cavity, and allowing it to cool and solidify to form the desired shape. Acrylic, a transparent and...

by hyx mold | Feb 4, 2024 | plastic mold manufacture

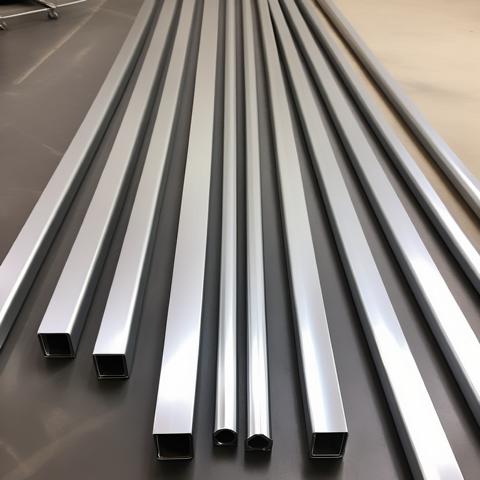

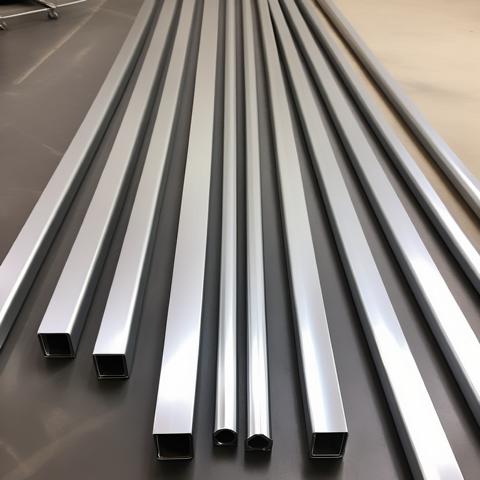

Unveiling the Differences: 6063 vs 6061 Aluminum Alloys Aluminum alloys play a pivotal role across various industries, thanks to their remarkable properties. Among the plethora of aluminum alloys available, 6063 and 6061 stand out prominently. Understanding the...

by hyx mold | Jan 24, 2024 | plastic mold manufacture

Unveiling the Excellence of Aluminum High-Pressure Die Casting: A Comprehensive Guide In the realm of precision manufacturing, aluminum high-pressure die casting stands as a cornerstone, pushing the boundaries of what is achievable. This article delves into the...

by hyx mold | Jan 6, 2020 | plastic mold manufacture

Outdoor Garden Chair Molds this article is mainly talk about outdoor garden chair molds,outdoor garden chair molds design,outdoor garden chair molds technologies,outdoor garden chair molds supplier,sell outdoor garden chair molds,buy outdoor garden chair molds,custom...

by hyx mold | Dec 26, 2019 | plastic mold manufacture

Cap molds with high quality supplied by HYX mould from China.HYX mold is a professional plastic mold manufacturer.Cap have many different types ,here let me introduce the standard cap mould -28mm .1. Cap mold cavities could based on customer’s...

by hyx mold | Dec 17, 2019 | plastic mold manufacture

First of all, a little R and R and R The truism is so drained it nearly may appear “lessen, reuse, reuse” ought to abandon saying. The greater part of us has just truly heard the last third of the expression, and they’re positioned arranged by...